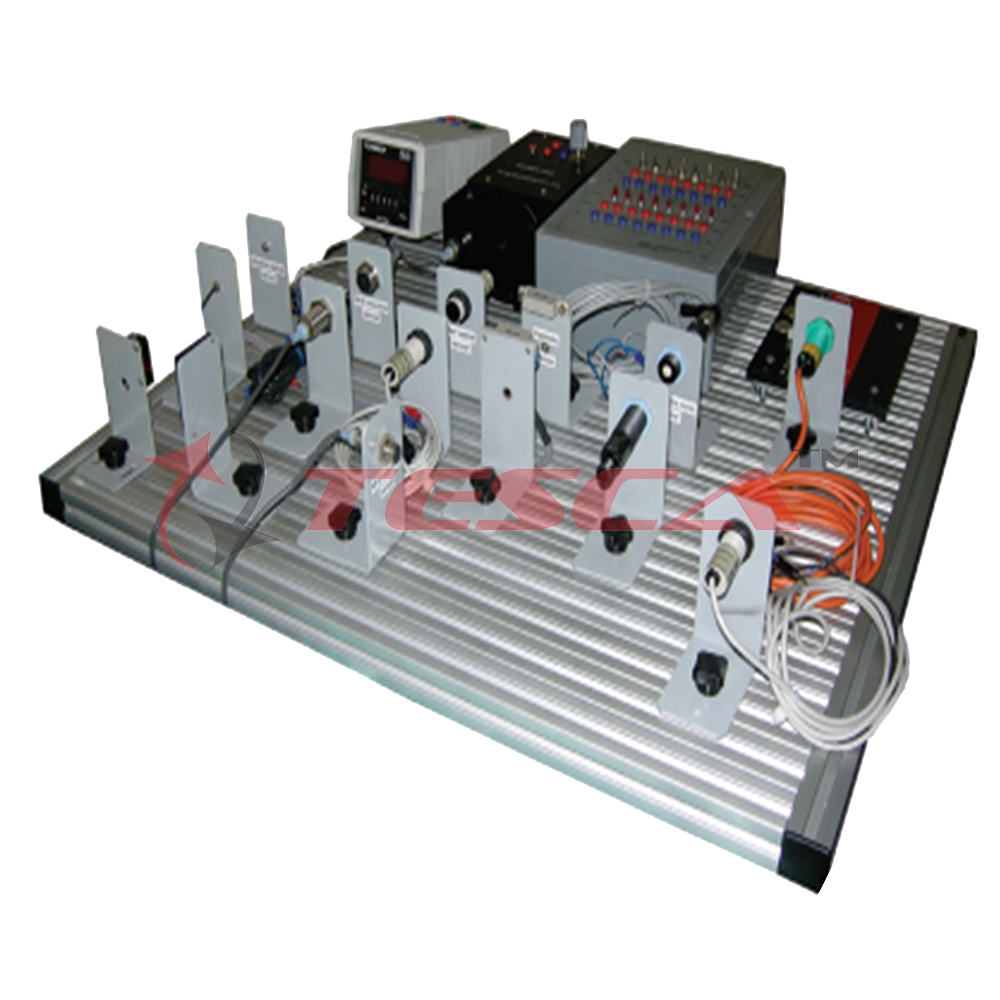

Digital Sensor Training Kit

Order Code: 54027

Category: Mechatronics/ Robotics/ CNC Lab

Sensors make the foundation of automation and Internet of Things in order to communicate state of device from operations, maintenance, performance, application perspectives. Understand & discern the functionality, response of various discrete sen...

SPECIFICATION

Sensors make the foundation of automation and Internet of Things in order to communicate state of device from operations, maintenance, performance, application perspectives. Understand & discern the functionality, response of various discrete sensors, switches, counters & other measurement devices and also learn about combining and measuring these devices as a whole or as an individual unit. The kit includes several industry standard sensors used in diverse engineering, process and automation applications. The Sensor Trainer can work as a stand-alone system or combined with PLC . As stand-alone system, the equipment can be used in disciplines such as STEM (physics) learning, electrical and electronics,

instrumentation, mechatronics, automation, manufacturing

Learning Objectives:

- Having successfully completed this lab, the student will demonstrate knowledge in

- Basic Sensor Technology / Sensors & Transducers

- Study of Sensors, transducers & their classification

- Study of Characteristics of sensor.

- Dynamic analysis of their performance / measurement of sensors.

Digital Sensor Module

Construction - Built on an aluminium profile plate, this trainer offers to build the concepts of basics in sensor technology, with a focus on digital sensors prevalent in the current industry. Advanced industry applications and experiments along are presented here through utilization of industrial components. This trainer has a single sided workstation upon which the following components can be easily mounted to build simple applications & conduct experiments. Each sensor kit has been offered as standalone kit incl. Base Al. Profile plate and necessary measuring equipment

|

SPECIFICATIONS |

|

|

Aluminium profile plate for mounting the components with appropriate number of mounting brackets |

1 no. |

|

Distribution unit with power supply, 16 banana sockets & Switches |

1 no. |

|

Digital multimeter |

1 no. |

|

Digital Vernier caliper 0 - 150 mm |

1 no. |

|

Counter unit with digital display for frequency |

1 no. |

|

Rotary drive unit DC motor with drive module for Speed/ frequency measurement |

1 no. |

|

Positioning slide for work price |

1 no. |

|

Steel Ruler - 1000 mm long |

1 no. |

|

Inductive proximity sensor M12 |

1 no. |

|

Inductive proximity sensor M18 |

1 no. |

|

Non contact inductive magnetic sensor |

1 no. |

|

Reed switch |

1 no. |

|

Optical sensor through beam transmitter |

1 no. |

|

Optical sensor through beam Receiver |

1 no. |

|

Optical sensor Retro - reflective |

1 no. |

|

Reflector |

1 no. |

|

Diffused reflective optical sensor |

1 no. |

|

Diffused reflective Fibre optic sensor head |

1 no. |

|

Through beam fibre optic sensor head |

1 no. |

|

Amplifier for fiber optic sensor(common for both head) |

1 no. |

|

Micro limit switch |

1 no. |

|

Capacitive sensor M 18 |

1 no. |

|

Ultra sonic proximity sensor M18 |

1 no. |

|

Test pieces |

1.SET |

|

24v dc power supply |

1 no. |

Technical Literature : Sensor Manual with Exercises (CD) 1 CD

DIMENSION : 630 x 460 x 250 mm

Weight : 30 kg (approx.)

Packed Dimensions : 730L x 560W x 550H weight - 65 kg approx.

Training Skills–

- Mode of Operation & Sensors properties

- Electrical connections & Electrical Circuit diagram Study

- Study of application of sensors

- Sensing range study with Different materials & sizes

- Study of application of sensors

- Actuating limitations

- Designs overview

Experiments –

- Some of the standalone & practical exercises for the training system are as follows,

- Drive module rotation measurement of rotary drive unit using counter unit

- Measurement of Current ratio variation depending on load variation with Multimeter.

- Speed/ Frequency measurement of the rotary drive module

- Measurement and comparison of linear position - drive module for varying load and frequency control

- Experiments for validating the various capabilities and response of different types of sensors with different

- conditions for (Inductive, ultra sonic, reflective, Fibre optic sensors etc.).

Set Of Standard Operation Tools

Allen Key----------------- Set 1

Screw Driver------------- Set 1

91-9829132777

91-9829132777